-

About UsMTL has been focusing on investment casting, including not only carbon steel metal components, but also stainless steel products and alloy steel products.

-

-

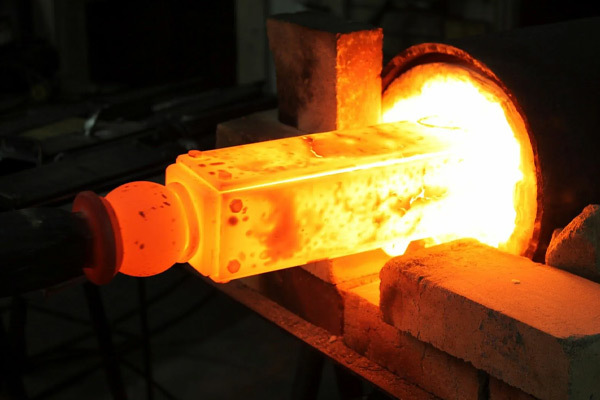

FactoryMTL has been focusing on investment casting, including not only carbon steel metal components, but also stainless steel products and alloy steel products.

-

NewsMTL has been focusing on investment casting, including not only carbon steel metal components, but also stainless steel products and alloy steel products.

Your One-Stop Metal Products Solution. Foundry ,Machining, Surface Treatment.

Jun 10,2025

Die casting (pressure casting) is a molding process that presses molten metal into a precision mold cavity at high speed to obtain high-precision, complex-shaped parts. Its core advantage lies in its high efficiency, precision, and complex molding capabilities, and is widely used in fields such as automobiles, electronics, and home appliances that require high mass production and surface quality. The following are the main advantages of die casting and typical application scenarios:

May 14,2025

Forging is a processing method that applies pressure to plastically deform a metal blank to obtain parts with certain shapes, sizes and mechanical properties. Its core advantages are to improve the performance of metal structures, increase material utilization, and achieve mass production. It is widely used in the manufacture of key components with high strength and toughness requirements. The following are the main application areas and typical application scenarios of forging:

CONTACT US

Office Add:No. 51 Fuqian St., EDZ, Dongying, Shandong, 257091 China

Plant Add:No. 88 Lingzhihou St., EDZ, Gaomi, Shandong, 261500 China

POPULAR PRODUCTS

CONSULTAR

Copyright : Dongying Maitlai Import and Export Co., Ltd. Powerby : CEGLOBAL | SEO | Privacy agreement