Auto Parts

1. Supply high-precision cast automotive parts that comply with IATF/ISO standards. Widely used in braking, chassis, transmission, suspension, engine peripherals, connectors, etc.

2. High dimensional precision, excellent strength, and lightweight design meet the requirements of harsh working conditions.

3. Strict quality control, ensuring stable and durable performance of key components, guaranteeing safety and long service life.

4. Support customized development based on images and samples.

OUR FORGING SOLUTIONS

We offer you different types of casting equipment, ensuring accuracy and precision.

TECHNICAL SUPPORT

Our primary business is casting and forging. We also offer a range of machining services. Within each of our broader product categories, we offer a wide range of related products. With over 10,000 products, we can help you along your journey.

You won't have to look far for any casting with us! We handle a wide variety of castings, from gravity casting to lost wax casting, including sand casting and silica sol processes.

We adhere to high material standards and have achieved high quality management certifications. Beyond quality, we also maintain an extensive inventory and offer a wide selection of different materials.

We strive for excellence and never miss out on any metalworking opportunity. We offer a wide range of metalworking processes, including laser cutting, plasma cutting, bending, nibbling, punching, stamping, and welding.

Putting our customers first, we offer the widest range of metalworking thicknesses. Furthermore, we prioritize aesthetics and utilize high-quality surface treatments. We handle a wide variety of welded and stamped parts.

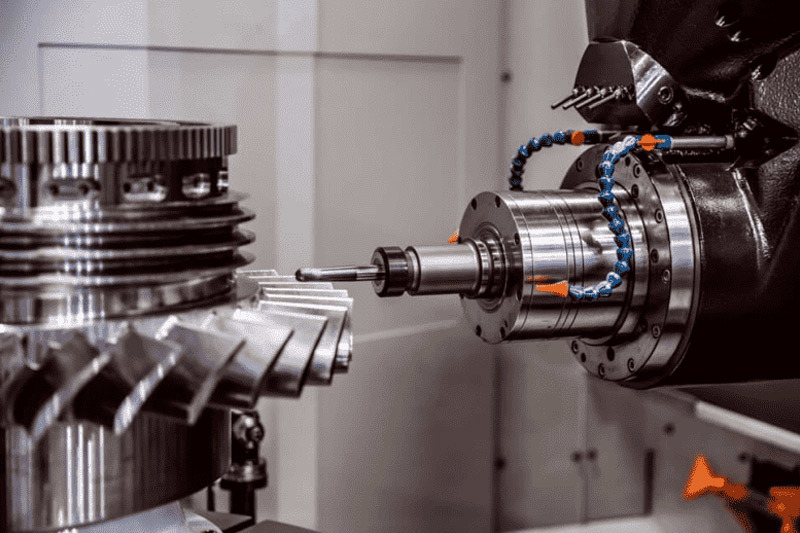

Our CNC machines ensure top-notch precision and accuracy.

Uncompromising on precision, we've expanded our machining range to include a wider range of materials, expanding our options. We've introduced new equipment and heat treatment processes. With such a diverse range of machining options, you can be assured of our unwavering commitment to quality.

Whether it's hot forging, die forging, or precision forging, we can do it all.

We enhance the toughness of forged components and use standard materials, making them ideal for a wide range of stresses. We also offer custom design and production solutions, ensuring your safety because we always put you first!

WHY CHOOSE US

Products Material Standard: ISO, GB, ASTM, SAE, ISO, EN, DIN, JIS, BS

Further Production Processes include Deburring,Sandblasting, Machining, Heat Treatment, Surface treatment, etc.

2D & 3D Drawings (Igs, PDF, JPEG, DWG, CAXA, UG, Stp, etc.) could be made and provided based on the samples.

Available software: Pro/E, Auto CAD, Solid work.

Further Production Processes include Deburring, Sandblasting, Machining, Heat Treatment, Surface treatment, etc.,

Precision machining, diverse heat treatment process, and rich surface treatment (Galvanized/Powder coating/KTL(/EPD)/Dacromet/Geomet) available

Mould material: Cr12, 4Cr5MoSiV1, 4Cr5MoSiV, etc.

WE STRIVE TO LEAD THE INDUSTRY WITH PERFECTLY

PRECISE ENGINEERING SOLUTIONS

Further Production Process:

1. Equipment: Laser Cutting Machine, Bending Machine, Punching, Nibbling Machine, Press Machine, CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine, and so on;

2. Heat Treatment: annealing , carbonization, tempering, quench, normalization and surface tempering

3. Surface treatment: Powder coating, Anodization, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc.

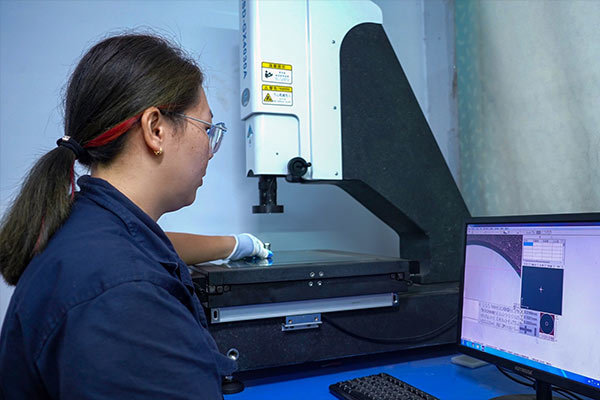

Quality control:

1. Samples and trial runs will be strictly inspected during production and before shipment

2. Test equipment: Spectrum Analyzer, CMM, Hardness test equipment, Tension test machine;

3. After-sales services are available.

4. Quality situation can be traceable.

Application:

1. Engine parts,

2. Auto parts,

3. Machinery Parts,

4. Rail Train parts,

5. Truck Parts,

6. Tractor Parts

7. Construction Equipment

8. Agriculture Equipment,

9. Other industrial fields.

– Carbon Steel: 10#, 15#, 20#, 25#, 30#, 35#, 40#, 45#, 50#, 55#…etc.

– Alloy Steel: 15Mn, 16Mn, 40Cr, 42CrMo…and other alloy steel.

– Stainless Steel: SUS304, SUS316, SUS316L, etc

– Aluminum: 6061 T6, 6063 T6

1. OEM & ODM both accepted. Products can be designed and produced as per customer’s requirements in forms of Samples, Drawings or even just a draft idea.

2. Over 20 years of experience in casting, welding, forging and precision machining for US, European and other overseas markets.

4. Package: Carton Box, PlyWood Box, Standard Export Pallets or as per customers’ requirements.

QUALITY INSPECTION

MTL castings always provide customers with high-quality services and qualified products. At present, the factory covers an area of 6000 square meters, with convenient transportation and close proximity to Qingdao Airport and Qingdao Port.

APPLICATION INDUSTRY

We focus on investment casting, customize high-precision, high-performance castings for multiple industries, and enable industrial upgrading.

Cement Industry

Shipbuilding

Ocean Engineering

Oil & Gas

Power Genratoin

Manufacturing

Steel Structure

Pipeline

Automotive

FAQ

Our company creates a professional network for sales and services, extends its reach of services over the globe, sets up an integrated system for pre- during and post sale services.

Q:Who are we?

A:Since 2011, MTL has been focusing on investment castings, including not only carbon steel metal parts, but also stainless steel products and alloy steel products.As a pioneer in automotive parts, we are committed to agricultural machinery, fluid equipment and building hardware. Pursue excellence and exceed expectations. MTL always provides customers with quality services and qualified products. The current factory covers an area of 6000 square meters, with convenient transportation, close to Qingdao Airport and Qingdao Port. We have more than 200 workers.Our facilities include a full set of investment casting equipment, CNC, stamping machines and polishing machines.All of these help MTL meet the different requirements of customers.

Q:How does your factory do regarding quality control?

A: We have professional QC team to inspect each items from the links of production to package.

Q:What is the biggest difference between you and other sellers?

A:MTL always provides customers with quality services and qualified products. The factory currently covers an area of 6000 square meters, with convenient transportation, close to Qingdao Airport and Qingdao Port. We have more than 200 workers.Our facilities include a full set of investment casting equipment, CNC, stamping machines and polishing machines.

Q: Can I get a better price?

A: Of course, since we are a manufacturer, we will be able to provide you with the best factory price.

Q:What can you buy from us?

A:Focus on investment castings, not only carbon steel metal parts, but also stainless steel products and alloy steel products.

Q: How do we ensure quality?

A: Always pre-production samples before mass production; Always final inspection before shipment;