Jun 10,2025

Core principles of precision machining

Precision machining is a machining technology that uses high-precision equipment and processes to achieve extremely high levels of dimensional accuracy, shape accuracy and surface quality of parts. Its core principles can be analyzed from the following aspects:

May 21,2025

Investment Casting Applications

Core components: Turbine blades (single crystal high temperature alloy blades, the complexity of the internal cooling structure reaches the micron level). Engine casing (integrated structure, reducing 300+ assembly welding points, improving reliability).

Apr 16,2025

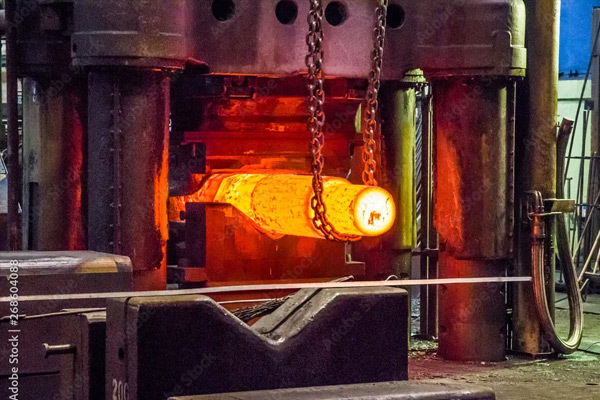

Investment Casting Core Principles

The shape of the part is reproduced by wax mold, and the wax is melted away after the refractory shell is formed by utilizing the solubility of wax (melting point is about 50-70℃), forming a complete cavity without parting surface, avoiding the problem of mold dislocation in traditional sand casting. Key steps:

Mar 12,2025

Advantages of precision machining

Precision machining refers to the processing technology that uses high-precision equipment and processes to make the dimensional accuracy, surface quality, geometric tolerances, etc. of parts reach extremely high standards. Its core advantages are reflected in high precision, high quality, high stability and multifunctional adaptability. It is widely used in aerospace, precision molds, optical instruments, medical equipment and other fields with strict precision requirements. The following are its main advantages and specific descriptions:

Feb 20,2025

Simplified mold structure Sand gravity casting: Using wooden or metal molds, no complex core pulling and ejection mechanisms are required, the mold production cycle is short (1-2 weeks), and the cost is only 1/10-1/5 of the die-casting mold.

Jan 23,2025

Advantages of Precision Casting

Precision casting (also known as lost wax casting, investment casting) is a casting technology that produces high-precision, complex-shaped parts through precise molds and complex processes. Its core advantages are reflected in high precision, low roughness, complex structure molding capabilities, and wide material adaptability. The following is a detailed analysis of the advantages:

Dec 18,2024

Sand casting is a casting process with a long history and wide application, mainly used to manufacture metal parts. It uses sand as the main molding material, and completes the molding of parts through molding, box assembly, pouring and other processes. The following is a detailed introduction to sand casting:

Nov 13,2024

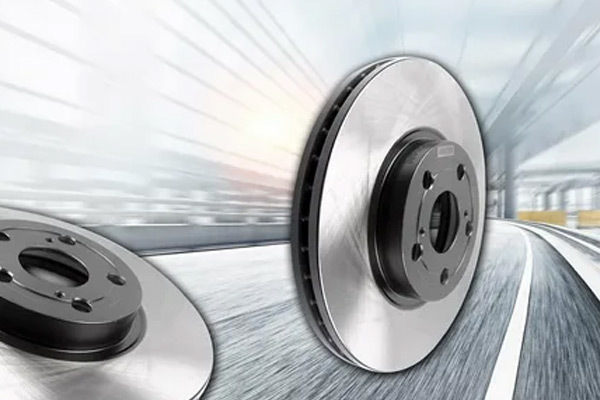

Importance of Xinyi Brake Disc

Sensitive braking: Xinyi brake discs usually use high-quality alloy materials and advanced manufacturing processes, which can quickly respond to the action of the brake pedal, allowing the vehicle to decelerate in a short time. In case of emergency, the driver can brake the vehicle in time to avoid accidents such as collisions.