Categories

Contact Us

E-mail :

info@mtl-castings.com

WhatsApp:

+86-13905463555

Address:

Room 1801, Ward Center, No. 51, Fuqian Street, Development Zone, Dongying City, Shandong Province

Valve Hardware Castings

- Commodity name: Valve Hardware Castings

Keywords:

Valve Hardware Castings

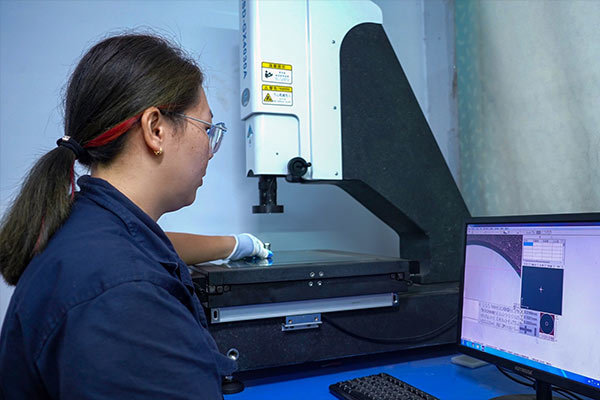

Quality Assurance

Strict quality inspection.

Delivery Method

Send in the best possible way

Delivery Time

Usually 15-30 days

PRODUCT DETAILS

1. Core components of precision cast pump valves: valve body, impeller, pump casing, etc.

2. Provide materials such as stainless steel and alloy steel, which have excellent corrosion resistance, high pressure resistance, and wear resistance.

3. High dimensional accuracy, excellent surface and intrinsic quality ensure reliable operation of fluid systems..

4. Provide solutions for complex structural castings and support customization.

Valve hardware castings are an essential component in a variety of industrial applications, ensuring both durability and precision in valve systems. These castings are typically made from high-quality metals such as stainless steel, cast iron, or alloys, which provide excellent resistance to corrosion and wear. The casting process itself involves pouring molten metal into a mold to create the desired shape, which is then cooled and finished to meet specific engineering standards.

One of the primary advantages of valve hardware castings is their ability to handle high-pressure environments, making them indispensable in industries such as oil and gas, water treatment, and chemical processing. The casting process ensures that each component is produced with the necessary strength and integrity to withstand harsh operating conditions.

In addition to their functionality, valve hardware castings also contribute to the overall efficiency of a system. The precision with which these castings are made ensures a tight seal in the valve mechanism, preventing leaks and enhancing the performance of the system. This is especially important in industries where even minor leaks can lead to significant safety hazards or operational inefficiencies.

Furthermore, the use of valve hardware castings can be cost-effective for manufacturers. The casting process allows for the mass production of parts with consistent quality, reducing the need for expensive machining and assembly work. This helps in maintaining lower production costs, which can be passed on to the consumer.

PACKING AND DELIVERY

Convenient transportation, close to Qingdao Airport and Qingdao Port. Quick delivery of products to you.

QUALITY INSPECTION

MTL castings always provide customers with high-quality services and qualified products. At present, the factory covers an area of 6000 square meters, with convenient transportation and close proximity to Qingdao Airport and Qingdao Port.

APPLICATION INDUSTRY

We focus on investment casting, customize high-precision, high-performance castings for multiple industries, and enable industrial upgrading.

Cement Industry

Shipbuilding

Ocean Engineering

Oil & Gas

Power Genratoin

Manufacturing

Steel Structure

Pipeline

Automotive

FAQ

Our company creates a professional network for sales and services, extends its reach of services over the globe, sets up an integrated system for pre- during and post sale services.

Q:Who are we?

A:Since 2011, MTL has been focusing on investment castings, including not only carbon steel metal parts, but also stainless steel products and alloy steel products.As a pioneer in automotive parts, we are committed to agricultural machinery, fluid equipment and building hardware. Pursue excellence and exceed expectations. MTL always provides customers with quality services and qualified products. The current factory covers an area of 6000 square meters, with convenient transportation, close to Qingdao Airport and Qingdao Port. We have more than 200 workers.Our facilities include a full set of investment casting equipment, CNC, stamping machines and polishing machines.All of these help MTL meet the different requirements of customers.

Q:How does your factory do regarding quality control?

A: We have professional QC team to inspect each items from the links of production to package.

Q:What is the biggest difference between you and other sellers?

A:MTL always provides customers with quality services and qualified products. The factory currently covers an area of 6000 square meters, with convenient transportation, close to Qingdao Airport and Qingdao Port. We have more than 200 workers.Our facilities include a full set of investment casting equipment, CNC, stamping machines and polishing machines.

Q: Can I get a better price?

A: Of course, since we are a manufacturer, we will be able to provide you with the best factory price.

Q:What can you buy from us?

A:Focus on investment castings, not only carbon steel metal parts, but also stainless steel products and alloy steel products.

Q: How do we ensure quality?

A: Always pre-production samples before mass production; Always final inspection before shipment;